Indexable Milling Cutters

WAX Wavemill - dry machining aluminium and non ferrous metals

Developed to overcome chip adhesion problems when machining aluminium caused by the chip welding itself to the face of the insert, this first ever solution for dry machining aluminium (used with MQL system) is ideal for high productivity machining aluminium parts to exacting tolerances in the Aviation, Electronics and Automotive industries. The award winning Aurora coat DLC coated inserts feature a self lubricating surface and anti welding properties designed to resist chip adhesion and substantially increases both productivity and tool life. This versatile cutter ranges from 20 -125mm diameter with cutting speeds to 1200mm/min and feed rates to 0.25mm/tooth. Dry machining aluminium eliminates the cost of applying and removing coolant and makes for a cleaner working environment boosting compliance with ISO 14001 accreditation standards.

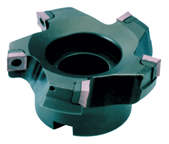

WRCX - 16 corner polygon insert cutter you can't manage without

The all new Wavemill WRCX multi purpose milling cutter provides high feed rates, vibration free machining and low cutting forces generating excellent surface finish and tight tolerances. With face milling, slotting, helical milling, boring, plunging and profiling capability, it's unique design features 16 corner polygon inserts and a durable cutter body forged from high tensile alloyed steel protected by a hard surface treatment. Suitable for carbon steels, alloy steels, stainless steels and high temperature alloys no machine shop should have to manage without the WRCX cutter in it's range of available tools.

SumiWdge Mill cast and ductile irons

Designed for rapid metal removal when machining cast and ductile iron, the 15 degree semi shoulder cutter features tangentially mounted inserts to maximise the amount of teeth in contact with the workpiece. Cutters range from 3 to 6 inch diameters in standard or fine pitch and utilise newly developed coated insert grades ACK200 / ACK300 at speeds between 600 to 900 SFM cast iron and ACK100 / ACK200 at speeds between 450 to 750 SFMfor ductile cast iron. Specify G for general purpose application and H for heavy interrupted cuts or unstable machining conditions.

Wavemill WEX - soft cutting action - whisper quiet

Building our successful Wavemill programme WEX cutter bodies benefit from a highly durable surface treatment and improved method of insert clamping. The wave shaped cutting edges generate lower cutting forces, whilst the high shear cutting action ensures soft reliable cutting even when deep slotting or milling with low rigidity machines. With newly developed grades for steels and cast iron - prepare to be astounded by the soft quiet cutting action.

Auroracoat - Dry machines Aluminium

Newly developed and available on a wide range of milling cutters the intoduction of our British award winning Auroracoat milling tools for dry machining Aluminium makes using coolant a thing of the past The blue coloured coating which is smooth and hard combines with a self lubricating surface to provide anti weld properties which resist the built up edge condition generally experienced when milling Aluminium.The smooth hard surface maximises feed rates and tool life making the Auroracoat milling tools a "must have" for those machining Aluminium. Coolant costs are eliminated and so too is the contaminated air associated with cold coolant and hot parts. Dry machining Aluminium also boosts compliance with ISO 14001 accreditation".

Metal Slash Mill - Slashes cycle times

A new range of facemills featuring square inserts with four cutting edges slashes cycle times by substantially increasing feed rates.Suitable for rough milling steels,cast iron, die steels etc the Metal Slash Mills offer feed rates up to five times higher than conventional face mills with cutting speeds up to 200m/min and feed rates of 1.5mm/tooth The Sumitomo Metal Slash Mill lives up to its name.

RF4000 - High speed finishing Aluminium Alloys

Using both tungsten carbide or our superior PCD inserts this cutter is suitable for high precision machining at high speeds - VC=5000m/min.Capable of mirror finishing and roughing aluminium alloys and non ferrous metals the cutter utilises cartidges with PCD blades and wipers for finishing, and SDET carbide inserts for roughing. Hard anodised Aluminium Alloy cutter body (about 40% lighter than steel) makes setting fast, simple and accurate.

WGC - General purpose 45 degree face mill

Suitable for high speed machining Vc>400m/min with a tough light weight cutter body the WGC cutter range improves metal removal rates,flatness,dimensional accuracy and surface finish.This cutter utilises high precision moulded inserts realising G class performance at a greatly reduced cost. Range of chipbreakers available for general purpose milling, heavy cutting and Aluminium machining.

Wavemill Type WRC Facemill with Polygon Inserts

This cutter wasoriginally designed for the die mould milling but its high perforrmance features have considerably extended its application range making it suitable for face milling,slotting,helical boring, plunging and profiling in both diverse and numerous industry sectors. The unique 16 corner polygon inserts substantially reduce cutting force and dramatically increase productivity. Available with paired sets of inserts for vibration free machining.

Wavemill - Type WBMF Ballnose Finishing Cutter

The outstanding results obtained from this finishing cutter are due to the combination of its large sigmoid blade and precise clamping system making the cutter head extremely rigid. The WBMF cutter achieves an excellent machined finish greatly reducing secondary hand finishing and polishing operations.

Wavemill - Type WBMR Ballmill

Particularly suitable for die mould machining the WBMR replaceable insert ball nose endmill efficiently roughs complex profiles. Its high feed rate capabilitry is a direct result of a sharp cutting edge which is maintained during the cutting cycle by the purpose developed carbide substrate and ultrea hard ZX coating a product of nano technology.

Wavemill - Type WRM Repeater Mill

Utilising the same inserts as the WEM and WMM Wavemill cutters the Repeatermilloften referred to as a "porcupine cutter" is ideal for deep shoulder milling operations, where smooth cutting,efficient metal removal, and extended tool life are critical. Standard APMT/APET inserts mounted in a zig zag configuration make this cutter ideal for heavy roughing operations on most workpiece materials.

Wavemill Type WMM Multi Function

Utilising the inserts used in the WEM cutters this multi function cutter often referred to as a drillmill performs a variety of operations such as slotting - shoulder milling - ramping - pocketing - drilling - helical cutting, and eliminates the need to stock a variety of tools. Uses standard APMT/APET ultra hard ZX coated inserts for high feed rates and long tool life.

Wavemill - WFM series for square shoulder milling

This high shear square shoulder milling cutter with four wave formed cutting edges provides a soft cutting action at high feed rates. Suitable for milling steels and irons the precision moulded M Class inserts offer G class performance at a fraction of the cost.Available in diameters from 50mm - 200mm in both coarse and fine pitch these cutters utilise XDMT inserts in a variety of modern grades.

Wavemill Type WEM Face Mill - Endmills

Flying in the face of convention Sumitomo set out to produce a sharp edged, wear and heat resistant milling programme which would cost effectively revolutionise metal removal rates. Now a standard feature of its WEM style endmills,shellmills, and facemills, the Wavemill incorporates super thick high rake inserts, to maximise tool rigidity and significantly reduce cutting forces resulting in tnhe smooth cutting of a variety of workpiece materials at impressive feed rates.

Sumitomo's Newest DNH Milling Cutter Series

This cutter uses negative inserts with positive top form to give you superior metal removal rates. Numbered cutting edges, count them, 8 of them. This highly productive cutter will outperform the competitive 6 and 8 corner insert cutters Max Depth of Cut a whopping .118" Feed per tooth a huge .023" to .039" per tooth a 4 inch cutter, in a 3 inch wide cut, at maximum depth and minimum feed produces almost 40 cubic inches of material removed running at 112 inches a minute feed.